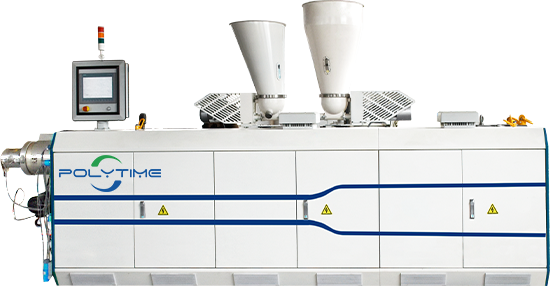

PVC yeeb nkab Extrusion tshuab

NugPVC yeeb nkab EXTRUSION LINE

PVC yeeb nkab

Cov kav dej PVC (piv rau PVC-U kav, PVC-M kav thiab PVC-O kav) Rigid polyvinyl chloride kav yog ua los ntawm polyvinyl chloride resin, stabilizers, lubricants, thiab lwm yam, thiab ces extruded los ntawm kub nias.

PVC-U Tube

PVC-U yeeb nkab yog siv rau cov kav dej, dej khib nyiab, tshuaj, cua sov thiab cua txias, khoom noj, dej ntshiab, av nkos, roj, compressed cua thiab lub tshuab nqus tsev.

- Technical Parameter -

| Txoj kab uas hla | Hom Extruder | Extrusion zog (kw) | Max. Peev xwm (kg / h) | Max. Tsheb khiav ceev (m / min) |

| Φ16-40 Dual | PLSZ51/105 | 18.5 Nws | 120 | 10 |

| Φ20-63 Dual | PLSZ65/132 | 37 | 250 | 15 |

| Φ16-32mm Plaub | PLSJZ65/132 | 37 | 250 | 12 |

| Φ20-63 | PLSZ51/105 | 18.5 Nws | 120 | 15 |

| Φ50-160 | PLSJZ65/132 | 37 | 250 | 8 |

| Φ75-160 Dual | PLSZ80/156 | 55 | 450 | 6 |

| Φ63-200 | PLSZ65/132 | 37 | 250 | 3.5 |

| Φ110-315 | PLSZ80/156 | 55 | 450 | 3 |

| Φ315-630 | PLSZ92/188 | 110 | 800 | 1.2 |

| Φ510-1000 | PIB 130/26 | 160 | 1100 | 1.3 |

- Qhov zoo -

CONICAL TWIN-Screw EXTRUDER

Zog

servo qhov system 15%

Far infrared cua sov system

Ua ntej cua sov

High Automation

Kev txawj ntse tswj

Kev saib xyuas thaj chaw deb

Formula Memory System

POM

POLYTIME Pwm R & D BU

Ceev cua sov tshuab

Tshwj xeeb ntws channel tsim

Optimized kub tswj

Internal txias system

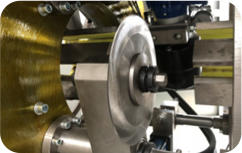

VACUUM TANK

Fast Cooling Nplhaib

Cov yeeb nkab qhov siab kev sib koom ua ke kho

Kho lub kaum sab xis thov Vajtswv

2-Loops Loj Lim

Alfa Laval Kub Exchanger

Alfa Laval Kub Exchanger

Dej Gas Separtor

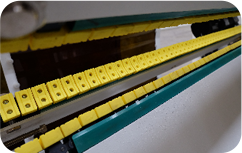

HAUL OFF

Kev sib txhuam coefficient yog nce los ntawm 40%, thiab kev pab cuam lub neej yog ob npaug

Nylon sawb tsim, zam cov saw loos los ntawm khib nyob rau hauv kev kub ceev khiav

Lub tshuab nqa nqa tau txais 2-theem tsim

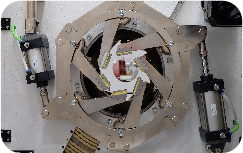

CUTTER

Siemens PLC tswj qhov systemNtse txiav tej chaw

Synchronous Device

Universal clamp

Ltalis Hydraulic System

Tsis-Plua Plav Txiav & Pom Txiav nrog Chamfering Function