PET Recycling Tshuab

Nug

80% los ua PSF (polyester fiber)

15% rau kev ntim khoom

5% los ua lub raj mis thiab lwm yam

PET Lub raj mis Recycling Ratio

Trends of the Industries

| Zoo | Daim Ntawv Thov Ntxiv | Tus nqi |

| Siab | Lub raj mis rau lub raj mis | Siab |

| Zaj duab xis los yog Sheet | ||

| POY | ||

| Mono-Filament, siab zoo PSF | ||

| Qib Qib qis | ||

| Qib qis PSF | ||

| Tsawg | Xim | Tsawg |

Ua lub raj mis rau lub raj mis cov khoom qib nrog tsim nyog peev thiab hloov dua siab tshiab.

Cov kab mob

Caps, Ntiv | Haus dej qab zib | Label (PVC, OPS, BOPP, Ntawv) | Kua nplaum

Av nkos, xuab zeb, roj, xim fwj, lwm yam polymer

Ntau tshaj 50% PVC L.abel

Qee lub raj mis PVC

Pre-sorted nrog hnyav av nkos,

Unforeseen Contaminants nyob rau hauv lub raj mis

30% PVC ntawv

Presorted nrog sib cais xim,

Cov kab mob tsis zoo PET

Aluminium Caps thiab Rings

Lub raj mis los ntawm Recycled Material

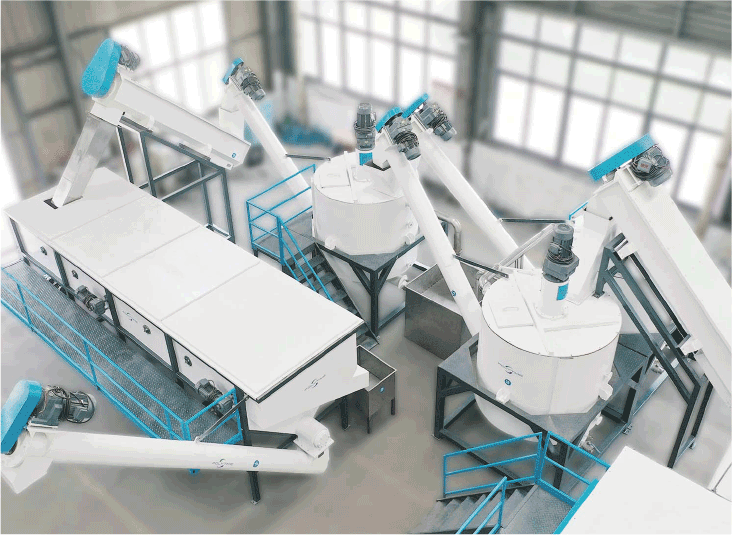

PET Washing Recycling Line

Nws yog tam sim no cov khoom tsis yog tus qauv, nws yuav yog cov kev daws teeb meem zoo raws li cov neeg siv khoom siv rau cov neeg ua lag luam hla kev lag luam, nws yuav siv sij hawm ntev los kawm. Txhawm rau daws qhov teeb meem no, Polytime Machinery tau tsim lub tsev tu modular rau cov neeg siv khoom xaiv los ntawm, uas yuav pab ua kom muaj kev sib txuas ua ke kom sai sai rau tag nrho cov kab tsim raws li cov yam ntxwv ntawm cov khoom siv raw.Modular cov cuab yeej tuaj yeem txo cov cuab yeej hneev taw thiab txuag nqi tsim. Polytime Machinery lub zog R & D pab neeg tsim kho tshiab hauv tshuab thiab sib tham txog kev nce qib nrog cov neeg siv khoom.

01 Debaler

02 Label Remover

03 Pre-washer

04 Optical Sorter

05 Phau ntawv sorting platform

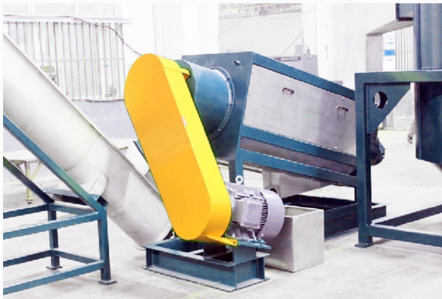

06 Crusher ua

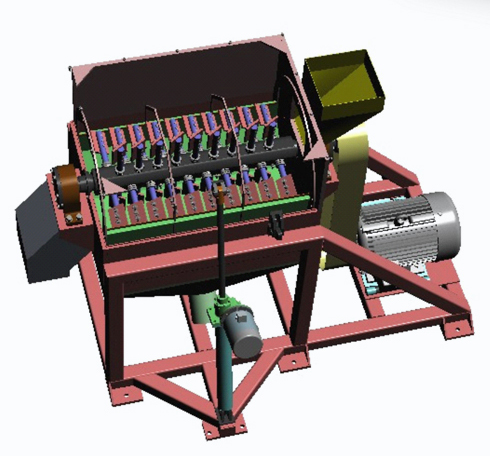

07 Friction Washer

08 Floating Separation Tank

09 Friction Washer

10 Kub Ntxuav System

11 High Speed Friction Washer

12 Centrifugal Tshuab ziab khaub ncaws

13 Floating Lim Ntxuav Tank

14 Dewatering tshuab ziab khaub ncaws

15 Thermol Pipe Line Dryer

16 Dust & Label Separator

17 Nyhav Pob Hopper

POLYTIME machinery muab customized ntau lawm kab tsim raws li. Los ntawm kev txheeb xyuas cov khoom siv raw thiab cov neeg siv khoom xav tau rau cov khoom kawg kom ua kom zoo dua qhov kev teeb tsa ntawm cov kab ntau lawm.Siv cov thev naus laus zis tshiab los txhawb lub ntiaj teb kev hloov pauv mus rau lub zog ruaj khov.

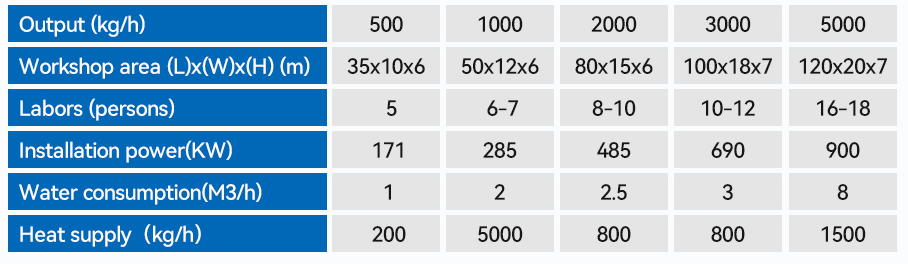

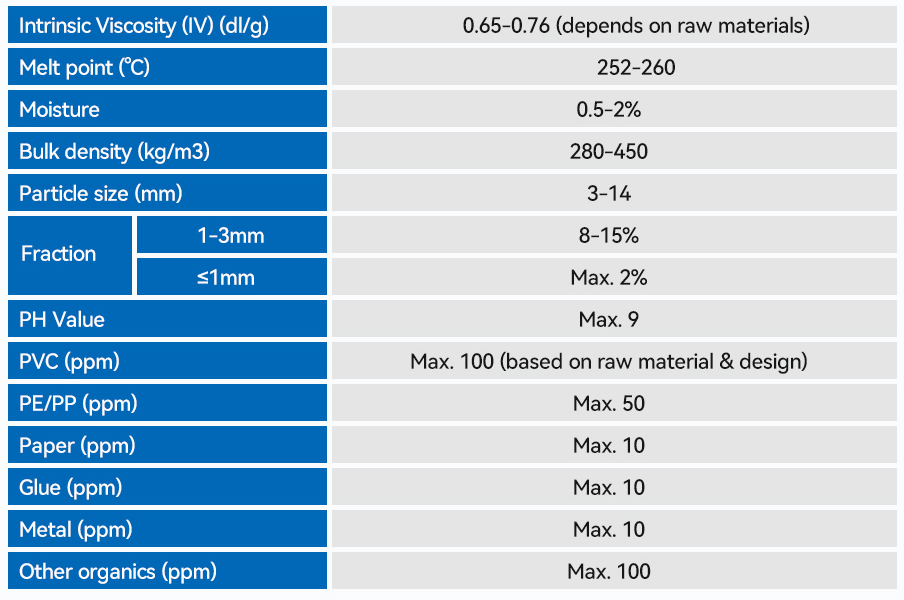

- Technical Parameter -

Muaj peev xwm & Cov ntaub ntawv yooj yim

Txheem cog loj (tso zis): 500kg/h, 1000kg/h, 2000kg/h, 3000kg/h, 5000kg/h

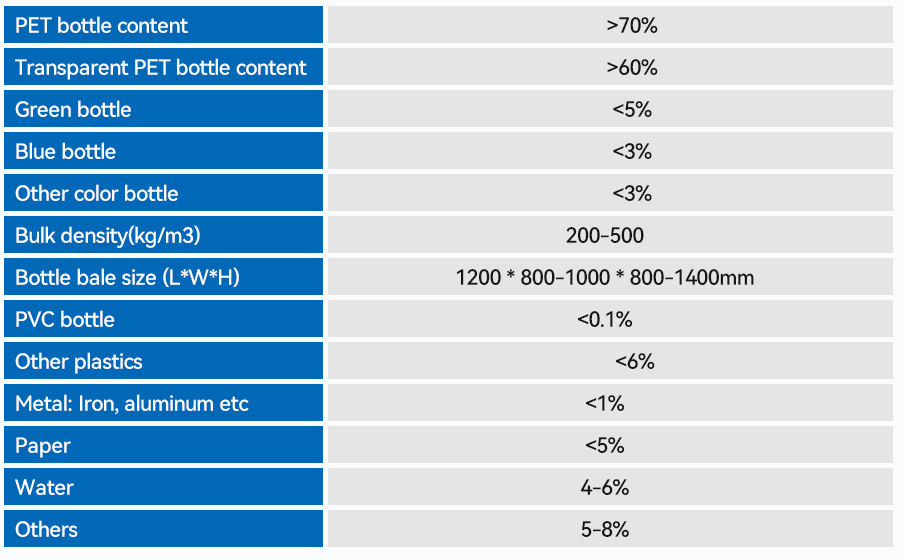

Cov ntaub ntawv xav tau

Qhov project xav tau kev hloov kho raws li qhov xwm txheej ntawm cov khoom siv

Specs ntawm cov khoom kawg --- PET flakes

- Qhov zoo -

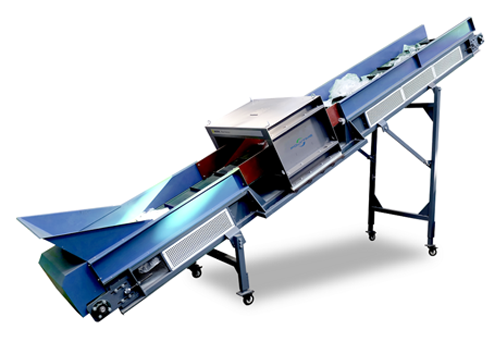

Inclined Conveyor Feed Belt

Inverter tswj

Lub ntug yog kaw los ntawm PVC sealing, uas yog

tsis yooj yim rau hnav thiab siv tau ntev.

Txais cov roj hmab lossis PVC, nruab nrog kev thaiv

strip raws li kev xaiv.

De-baler & Weighing Section

Manually txiav tawm cov bundling hlau los yog cov straps, siv ib tug forklift los muab lub bale rau hauv lub saw phaj conveyor.Lub raj mis bricks yog kis tawm mus rau ib tug npaum li cas, khaws cia ib co ntawm cov raw cov ntaub ntawv los xyuas kom meej lub uniformity thiab continuation ntawm ntxuav kab noj.

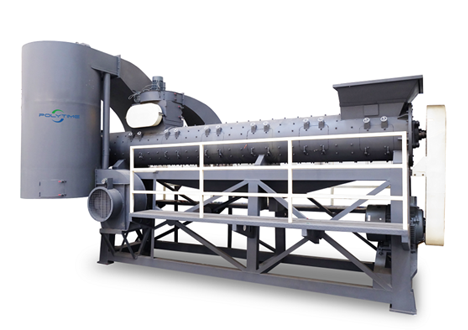

Trommel & Hlau Tshem Tawm Tshooj

Lub trommel ua tau zoo yog siv los cais cov sundries, pob zeb, iav, hlau cov khoom thiab lwm yam impurities nyob rau hauv cov ntaub ntawv raw los txo cov siab ntau lawm nyob rau hauv lub tom ntej theem, txo cov khoom hnav thiab muaj peev xwm noj, thiab zoo txhim kho cov khoom zoo.

Pre-xaiv & L abel Separation Unit

Nrog kev txheeb cais, variegated impurity fwj yuav raug xaiv rau ntau qhov loj.Label tshem tawm yuav rub txhua lub raj mis tig ntawm kev kub ceev, rhuav tshem daim ntawv lo nrog rau lub raj mis lub cev.Cov ntawv sau baling system yog siv los ntim cov ntawv sib cais thiab cov yeeb yaj kiab, txo txoj haujlwm ntawm tib neeg qhov chaw.

Lub raj mis Pre-wash Section

Nyob rau hauv lub zog nplawm, lub tshuab ntxhua khaub ncaws tas li uas ua ke lub zog ua haujlwm ntawm cov tshuab, chemistry thiab cua sov lub zog yuav sib cais thiab tshem tawm ntau dua 90% impurities. Tom qab ntawd cov txheej txheem cov cuab yeej yuav raug tiv thaiv kom zoo vim yog lub raj mis huv huv.

Ntub Dej Crusher

Thaum peb ncuav dej nrog cov khoom rau crushing chamber, kev sib txhuam ntawm crushed flakes thiab crusher rotor yuav ua rau thawj kauj ruam ntawm flake ntxuav. Thiab feem ntau ntawm cov kab mob yuav raug cais tawm ntawm flakes. Txawm tias cov ntawv nplaum, ntau ntawm lawv kuj yuav raug tshem tawm ntawm flake nto. Ntawm qhov tod tes, cov dej nchuav yuav txo qhov kub ntawm crushing chamber. Nws tiv thaiv lub neej lub sij hawm ntawm rotor, hniav thiab bearing.

Ntug dej sib cais

Lub raj mis lub cev yog crushed ua ke nrog lub hau thiab lub nplhaib, uas yog cov khoom siv PP / PE, cov khoom sib xyaw tom qab sib tsoo siv qhov sib txawv ntawm cov khoom sib txawv ntawm cov yas sib txawv, cov dej sib cais lub tank yuav ua rau PET flakes rau hauv lub dab dej thiab lub raj mis kom ntab, thaum ntxuav cov PET flakes rau thawj theem. PP / PE cov khoom yuav raug sau los ntawm cov khoom siv.

Kub Washer & Friction Washer Section

Thermal, tshuaj thiab mechanical rog yuav siv tau rau hauv lub tshuab ntxhua khaub ncaws kub. Kev sib txhuam ntawm lub raj mis flakes thiab lub zog shearing ntawm lub vortex ntawm cov tshuaj tov yog siv los tshem tawm impurities los ntawm qhov chaw ntawm cov flakes thiab tshem tawm los ntawm centrifugal dehydration.Nrog kev sib txhuam tsis tu ncua, lub tshuab ntxhua khaub ncaws ntab thiab lub tshuab ziab khaub ncaws centrifugal, tshuaj nyob rau saum npoo ntawm cov flakes yuav raug ntxuav, thiab PH tus nqi yuav nyob ze ntawm lub flakes.

Friction washer (tsawg ceev thiab siab ceev)

Tsawg ceev hom

Nrog ceev ntawm 600 rpm;

Nrog kev ua haujlwm ntawm kev pub mis;

Dewatering, deg sludge tshem tawm.

Kev kub ceev hom

Nrog ceev ntawm 1200 rpm;

Kev sib txhuam ceev;

Dewatering, deg sludge tshem tawm.

Centrifugal tshuab ziab khaub ncaws --- Dewatering

Kev kub ceev dynamic tshuav kho nrog ceev txog 2400rpm.

Cov dej noo tsawg dua 1.5%.

Pem hauv ntej ncej yog tsim los ntawm 45 # steel thiab npib tsib xee chrome plated ua kom muaj kev puas tsuaj thiab toughness.

Hniav lub kaum sab xis yog adjustable kom tau raws li flakes sib txawv dej conte.

Label Separation Section thiab pob system

Cais cov zaj duab xis nyias, hmoov thiab lwm yam khoom siv lub teeb nyob rau hauv lub raj mis flakes los ntawm huab cua tshuab tswj.Shake khoom, ntsuas thiab hnyav.

Hlau Txheej Txheem

Sib nqus hlau sib cais:

1. Permanent sib nqus siv style de-ironing separator, 0.1-35KG, hlau filings, hlau.

2. Permanent sib nqus nruas-style sorting tshuab. Sib nqus teb siv: 400-600GS

Non-magnetic non-ferrous:

Hlau eddy tam sim no sorting tshuab:

1. Nws tuaj yeem hloov kho rau ntau qhov ntau thiab tsawg ntawm cov khoom siv

2. Cov cuab yeej zoo ntawm demagnetization.

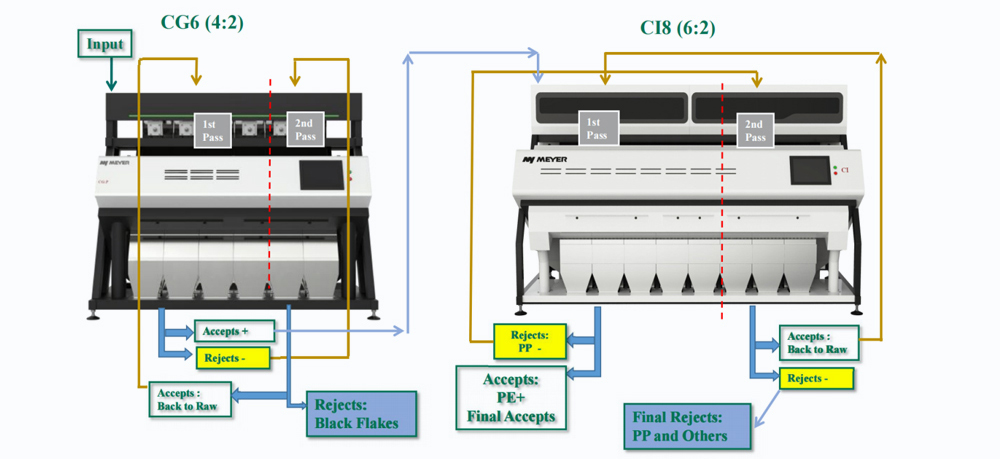

Intelligent Optical Sorting Equipment

Qee tus neeg muab khoom tseem ceeb thoob ntiaj teb:

NRT, USA (NIR);

T-TECH Lub teb chaws Yelemees (NIR);

MSS, USA (NIR);

Pellec Fabkis (NIR);

S+S, Lub teb chaws Yelemees (NIR);

MST, Suav teb (X-Ray).TOMRA